Laser Engraving Machines: Transform Your Creative Ideas into Reality

Laser engraving machines empower creators to turn imaginative ideas into tangible, precise works, while their cost remains a key consideration for anyone looking to invest. This guide explores the creative potential of these machines and breaks down the factors that influence their pricing.

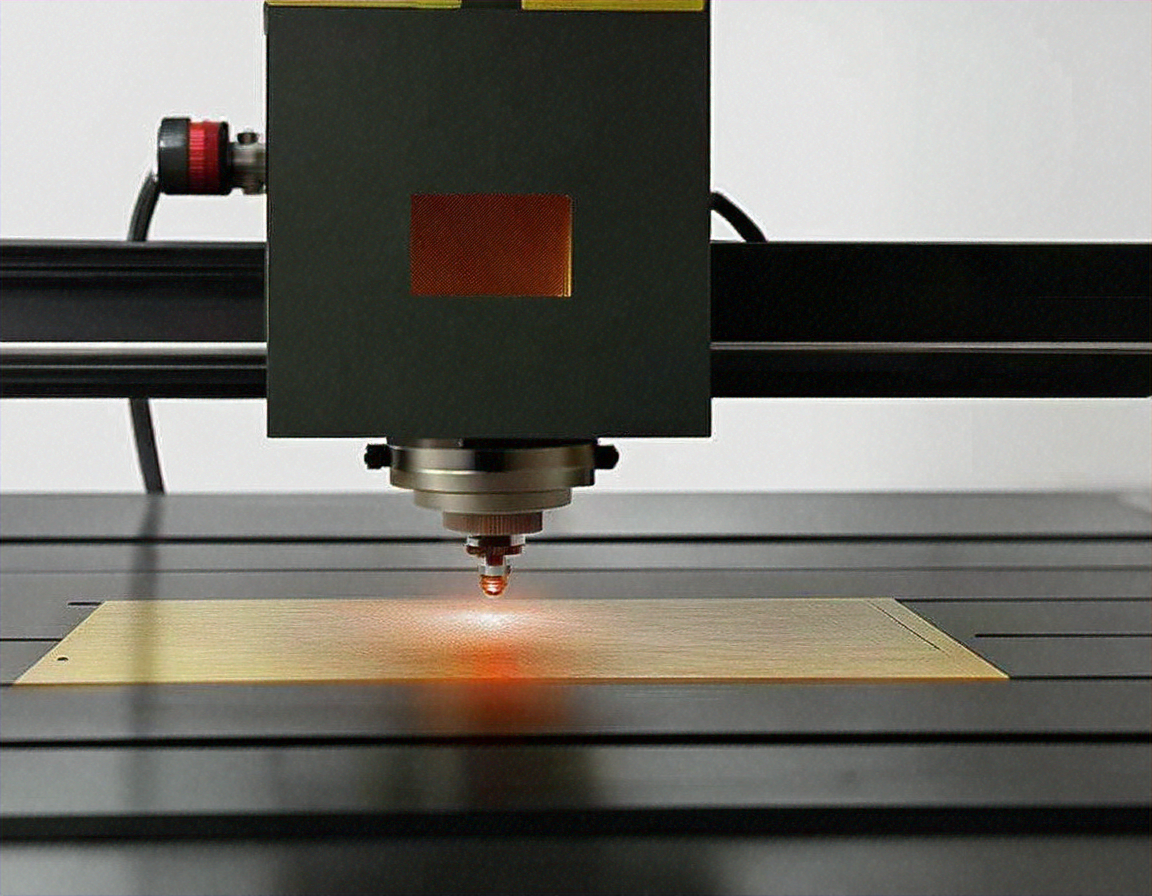

Laser engraving machines have transformed the creative landscape, offering unprecedented precision and versatility for artists, entrepreneurs, and manufacturers alike. These remarkable devices use concentrated beams of light to etch designs, text, and images onto various materials with exceptional accuracy. Whether you’re a hobbyist looking to explore new creative outlets or a business owner seeking to expand your product offerings, laser engraving machines provide the tools to turn imaginative concepts into tangible reality. The technology continues to evolve, becoming more accessible and capable while opening new possibilities across numerous industries and creative fields.

Creative Applications of Laser Engraving Machines

Laser engraving machines have sparked a creative revolution across multiple disciplines. In woodworking, these devices create intricate patterns and personalized designs that would be nearly impossible to achieve by hand. The jewelry industry has embraced laser engraving for adding minute details to precious metals and creating custom pieces with personalized messages. Leather goods benefit from precise marking that doesn’t compromise material integrity, while glass engraving produces stunning frosted effects and detailed imagery.

Creative professionals use these machines to customize everything from promotional products to wedding favors. Architectural model makers appreciate the precision when creating detailed scale representations of buildings. Artists have incorporated laser engraving into mixed media pieces, combining traditional techniques with technology-enabled precision. The ability to work with materials ranging from acrylic and cork to stone and certain plastics means that creative boundaries continue to expand as users discover new applications and techniques.

Key Factors Shaping Laser Engraving Machine Costs

Several critical factors determine the cost of laser engraving equipment. Laser type significantly impacts pricing, with CO2 lasers generally being more affordable for beginners while fiber and crystal lasers command premium prices due to their specialized capabilities. Work area size directly correlates with cost—machines that accommodate larger materials require more substantial components and engineering, increasing the price substantially.

Power output represents another major cost determinant, with higher wattage machines capable of cutting thicker materials and working at faster speeds. Software sophistication varies widely between models, with higher-end machines offering advanced features like automatic material recognition, camera positioning systems, and complex design capabilities. Build quality also influences longevity and precision, with industrial-grade machines featuring robust construction that withstands continuous operation. Additional features like autofocus, rotary attachments for cylindrical objects, and air assist systems for cleaner cuts further affect the final price point.

Budget-Friendly vs. High-End Laser Engraving Machines for Creators

Entry-level laser engravers typically range from $300 to $2,000, making them accessible to hobbyists and small businesses. These machines usually feature lower power outputs (20-40W), smaller work areas, and basic software interfaces. While they handle materials like wood, acrylic, and leather effectively, they may struggle with harder substances or require multiple passes for deeper engraving. Despite these limitations, budget-friendly options provide excellent value for beginners exploring laser technology.

In contrast, high-end professional systems starting at $5,000 and reaching $50,000+ deliver substantial advantages for serious creators. These machines offer larger work areas, higher power outputs (50W-150W+), and superior precision that ensures consistent results across production runs. Professional-grade systems also feature robust construction for continuous operation, advanced cooling systems, and sophisticated software with features like material libraries and advanced path optimization. The investment becomes justifiable for businesses requiring reliability, speed, and versatility across diverse materials and applications.

Essential Features to Consider When Selecting a Laser Engraver

When evaluating laser engraving machines, resolution and precision capabilities should be primary considerations. Higher-quality machines can achieve finer details, with some capable of engraving lines as thin as 0.1mm. Connectivity options also matter significantly—modern systems offer USB, Ethernet, and even Wi-Fi connectivity for seamless workflow integration. The control software’s intuitiveness directly impacts productivity, with better interfaces reducing the learning curve and streamlining operations.

Safety features represent another crucial aspect, particularly for shared spaces or educational environments. Look for machines with automatic shutdown capabilities, enclosed designs to contain laser emissions, and emergency stop buttons. Maintenance requirements vary between models, with some requiring regular alignment checks and cleaning while others feature self-maintaining systems. Finally, consider the availability of technical support and spare parts, as this can significantly affect downtime if issues arise. Manufacturers offering comprehensive warranties, training resources, and responsive customer service provide valuable peace of mind for your investment.

Laser Engraving Machine Market: Comparing Top Options

The laser engraving market offers diverse options across different price points and capabilities. Below is a comparison of notable machines currently available:

| Machine Model | Type | Work Area | Power | Key Features | Estimated Price |

|---|---|---|---|---|---|

| Glowforge Pro | CO2 | 20” x 18” | 45W | Camera positioning, cloud-based software, pass-through slot | $5,995 |

| Epilog Zing 24 | CO2 | 24” x 12” | 30-60W | High-speed engraving, vector cutting, industrial-grade construction | $19,995 |

| OMTech 40W | CO2 | 12” x 8” | 40W | Offline controller, Red dot pointer, LCD display | $399-$599 |

| Trotec Speedy 100 | CO2/Fiber | 24” x 12” | 60-120W | JobControl software, InPack Technology™, high-speed processing | $15,000-$30,000 |

| Full Spectrum Muse | CO2 | 20” x 12” | 45W | Camera alignment, touchscreen, 3D engraving capability | $3,499-$4,499 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Maintenance and Care for Optimal Performance

Proper maintenance significantly extends the lifespan and performance of laser engraving machines. Regular cleaning of lenses and mirrors prevents residue buildup that can degrade laser power and precision. Most manufacturers recommend daily cleaning of the work area to remove debris and monthly inspection of optical components. Alignment checks ensure the laser beam travels correctly through the optical path, maintaining precision and preventing potential damage to components.

Ventilation system maintenance proves equally important, as proper airflow protects both the machine and operator. Filters require regular replacement to prevent clogging that could allow harmful fumes to escape. For CO2 lasers, water cooling systems need monitoring to prevent overheating and maintain consistent performance. Creating a maintenance schedule based on usage frequency helps prevent unexpected downtime and costly repairs. Many professional users find that documenting maintenance activities helps track patterns and anticipate when components might need replacement, ultimately maximizing the return on their investment.

Laser engraving machines have democratized precision manufacturing and creative production, making once-exclusive capabilities accessible to creators at various levels. From hobbyists exploring new artistic expressions to established businesses expanding their product offerings, these versatile tools continue to transform how we bring ideas to physical form. As technology advances and prices become increasingly accessible, laser engraving will likely continue its expansion into new creative territories, empowering more people to transform their creative visions into reality with unprecedented precision and detail.